ABS & DNV APPROVED SOCKET-LOCK

Tech Specs

Country of Origin

Made in USA

MSDS

| Safety Information | |

|

Always work in a ventilated area. Avoid skin or eye contact. Wash skin with soap and water and remove contaminated clothing. If contact with eyes, flush with clean water for at least 15 minutes. If irritation persists, seek medical attention.

Avoid inhaling vapors. If excessive vapors are inhaled, move to a fresh air area. If breathing has stopped or is labored seek medical attention. Never aim an open flame at Socket Lock. Keep away from heat. Resin is a flammable liquid. Whenever using chemicals, always reference the MSDS sheet for safety and handling guidelines. |

| MSDS | |

|

|

|

|

Compliance & Restrictions

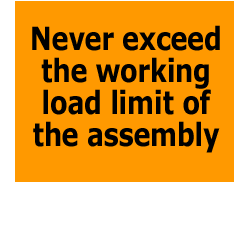

| Warnings | |

|

Only use soft annealed iron wire for seizing wire. Socket Lock resin must be gelled and cured before assembly can be used. Socket Lock is not to be used with stainless steel rope in a salt water environment. Never use oversized sockets for wire rope. Never use Socket Lock beyond the expiration date. Never heat socket prior to pouring resin in an effort to accelerate the curing of the resin as it may cause the resin to prematurely gel prior to reaching the bottom of the socket bowl. Doing this could cause the assembly to fail. Caution: Exposure to some strong chemicals may affect the cured polymer (hardened resin mixture) in a way that could weaken the assembly. Please contact Sea Fit, an authorized distributor or the manufacturer if this has occurred. |

When handling the resin or hardener, goggles and protective clothing are recommended. Impervious gloves are recommended.

When handling the resin or hardener, goggles and protective clothing are recommended. Impervious gloves are recommended. Avoid ingestion. If ingestion occurs,

Avoid ingestion. If ingestion occurs,